Image may be NSFW.

Clik here to view.

Can you manage what you can’t measure? Is monitoring your data center really the same as modeling it? Do you make IT changes, then cross your fingers that they’ll work?

There’s an old adage that you can’t manage what you can’t measure. As data center operators flock to DCIM to gather more and more information about their facilities, there’s a danger that some confuse monitoring as modeling.

DCIM is an incredibly valuable tool, providing a wealth of information vital to operation of a modern data center. But it’s not a panacea for the IT deployment process.

The specifics of the deployment process vary between organizations, but most data center operators are stuck in a reactive IT deployment cycle:

- Decide – Find a rack where environmental conditions are within acceptable thresholds and that has enough space, the right network connectivity and enough capacity on the breakers to support the equipment.

- Deploy – Install the equipment and power it up.

- Monitor – Watch the live data from the facility for any problems.

- React – If issues appear, be ready to react before they become critical.

Image may be NSFW.

Clik here to view.

Whilst DCIM tools certainly help with steps 1 and 3, allowing operators to react much quicker to any issues that arrive, they are still left reacting to problems. In many instances, those problems indicate that the IT deployment should have been made elsewhere.

So, how do you implement new hardware with confidence? How do you avoid firefighting problems in the future that could have been prevented with better information in the present. How do you overcome the fundamental limitation that monitor data from sensors can’t tell you what’s going to happen in the future?

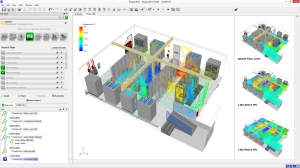

The solution lies in computer modeling. A data center works by well understood physical processes, and its behavior can be mimicked by a computer model. But get this: once a model has been verified to produce correct results for the current configuration, future configurations can be fed in and their behavior analyzed.

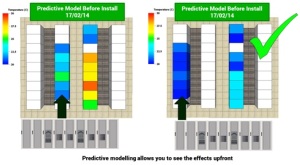

This is called predictive modeling. It allows the impact of a proposed deployment to be understood before a single work order is printed.

Predictive modeling paves the way for a proactive deployment process that exploits all of the good data from DCIM, but puts the operator on the front foot. It doesn’t even require a significant departure from current working practices:

- Predict – Predict the impact of the proposed change using the verified computer model.

- Decide – Use the results to guide the best deployment location based on operational considerations

- Deploy – Install the equipment and power it up.

- Monitor – Watch the live data from the facility for any problems.

Monitoring is still an integral part of the process, but it now works together with predictive modeling to give data center operators complete visibility into the state of their data center, now and in the future.

Image may be NSFW.

Clik here to view.

Supporting case study from CBRE:

http://dcimnews.wordpress.com/2013/11/21/cbre-white-paper-at-the-end-of-the-day-its-lost-capacity/

Contact Robert to learn more: http://www.linkedin.com/in/rfschmidt

Image may be NSFW.

Clik here to view.

Image may be NSFW.

Image may be NSFW.Clik here to view.